1300 980 625 | SALES@INDUSTRIALPUMPSAUSTRALIA.COM.AU

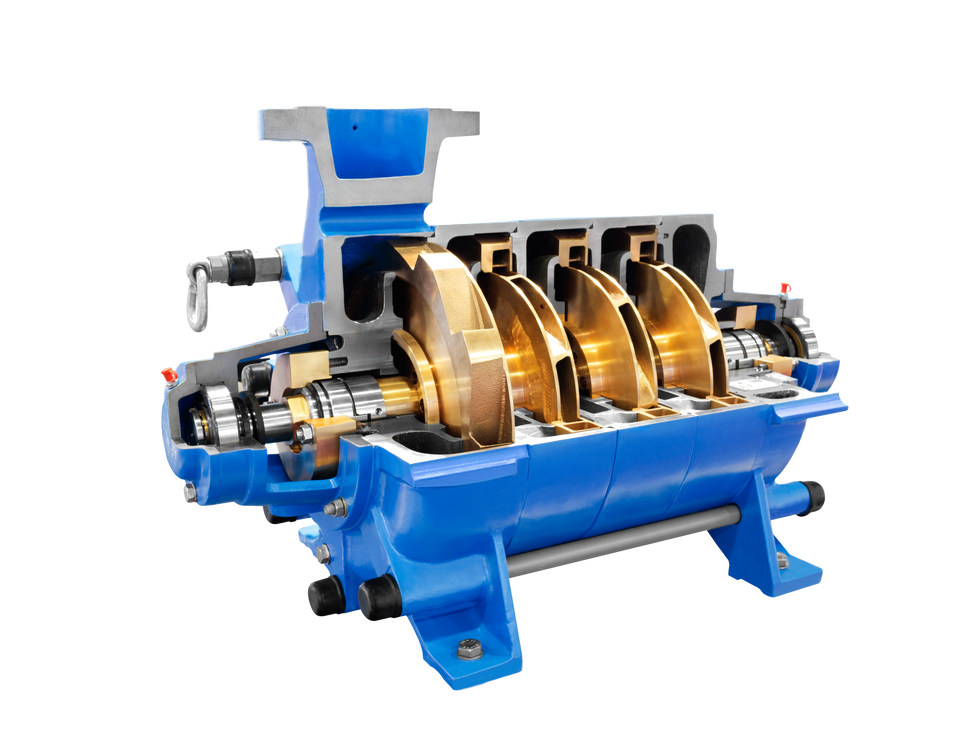

Multistage Pumps

Multistage Pumps are designed for high-pressure fluid transfer, offering efficiency and reliability in boiler feed systems, desalination, and mine dewatering. These pumps feature multiple impellers, including centrifugal and side-channel stages, to achieve the desired pressure and flow. Ideal for industrial, water, and mining applications, Multistage Pumps ensure optimal performance in demanding environments.

Multistage Pumps are engineered for high-pressure fluid transfer, providing reliable and efficient solutions in various industries. Featuring two or more impellers, these pumps use a sequential impeller system to achieve high-pressure flow, with the number of stages depending on the desired pressure requirement. The pump design ensures smooth operation in demanding conditions, reducing the risk of cavitation and improving overall system efficiency. These pumps are available in both Ring Section and Split Case designs, ensuring versatility for a wide range of applications such as boiler feed systems, desalination by reverse osmosis, and mine dewatering. Multistage pumps are commonly used in industries like power generation, water treatment, chemical processing, and mining, where consistent flow and pressure are critical for system performance.

KEY FEATURES:

Ring Section and Split Case Designs – Suitable for high-pressure applications with varying flow rates.

Multiple Impeller Options – Includes centrifugal, side-channel, and combination stage designs for different pressure needs.

Centrifugal First-Stage Impeller – Provides efficient initial pressure increase.

Side-Channel Stage Impeller – Enhances the pump's ability to handle liquids with low NPSH (Net Positive Suction Head) requirements.

High Efficiency – Reduces energy consumption while ensuring reliable performance.

Versatile Applications – Ideal for industrial, water, and mining applications.

TYPICAL APPLICATIONS:

Boiler Feed Systems – Reliable water supply for steam generation in power plants.

Desalination by Reverse Osmosis – Essential for seawater desalination processes, providing high pressure.

Mine Dewatering – Effectively handles the removal of excess water from underground mines.

Industrial High-Pressure Water Supply – Supports general industrial operations requiring consistent high-pressure water.

Multistage pumps are available in and vertical configurations, with options like submersible pumps and vertical turbine pumps for specialised needs.

We supply high-quality multistage pumps from leading brands like Flowserve SIHI, KSB Multitec, Sulzer, ITT Goulds, and more, ensuring reliable performance and energy efficiency.

For your demanding fluid handling requirements, Industrial Pumps Australia provides reliable, efficient multistage pump solutions. Contact us today to select the perfect pump for your application.

Boiler Feed Systems – Reliable water supply for steam generation in power plants.

Desalination by Reverse Osmosis – Essential for seawater desalination processes, providing high pressure.

Mine Dewatering – Effectively handles the removal of excess water from underground mines.

Industrial High-Pressure Water Supply – Supports general industrial operations requiring consistent high-pressure water.

TYPES OF MULTISTAGE PUMPS:

Horizontal Multistage Pumps - Designed for high-pressure applications with stable performance. Ideal for boiler feedwater, pressure boosting, and industrial processes. Available in stainless steel or cast iron for durability.

Vertical Multistage Pumps - Space-saving design with inline suction and discharge. Used for water supply, high-rise building pressure boosting, and reverse osmosis systems. Typically made from corrosion-resistant materials for longevity.

Submersible Multistage Pumps - Operates underwater for deep well pumping and borehole applications. Common in agriculture, municipal water supply, and dewatering. Available in various diameters to fit different well sizes.

High-Pressure Multistage Pumps - Designed for extreme pressure applications, such as firefighting and desalination. Robust construction with multiple impellers to maximise efficiency.

KEY SPECIFICATIONS OF MULTISTAGE PUMPS:

Flow Rate: Varies from a few liters per minute to thousands of cubic meters per hour.

Head (Pressure): Can exceed 1000 meters for specialised applications.

Material Options: Stainless steel, cast iron, bronze, and duplex alloys for different environments.

Motor Power: Ranges from small domestic units to industrial high-horsepower motors.

Seal Types: Mechanical seals or gland packing for different fluid compatibilities.

Efficiency: Optimised for energy savings with modern hydraulic designs.

CHOOSING THE RIGHT MULTISTAGE PUMP:

When selecting a multistage pump, consider -

Application Needs: Water supply, irrigation, industrial processes, etc.

Required Pressure and Flow Rate: Ensures optimal performance.

Material Compatibility: Prevents corrosion and ensures longevity.

Energy Efficiency: Reduces operational costs over time.

Get the Best Multistage Pumps for Your Industry

Looking for high-quality multistage pumps? Contact us today to find the perfect solution for your needs. We supply top brands and offer expert advice to help you select the right pump for your application and budget.